Polaris Sensor Technologies, Inc.

Polaris Sensor Technologies, Inc.

Polaris’s subject matter experts are on the cutting edge of hypervelocity aero-optics research. In the late 1990s, they provided modeling and simulation predictions and sensor requirements, set up optical sensors, and analyzed data for Hyper-Velocity Wind Tunnel No. 9 testing. This tested aero-optical effects on windows in Mach 7 high-enthalpy flow, simulating high-speed seeker flight at low altitude (15km).

Polaris is now developing and testing the Aero-Optics Kit (AOK) to better understand and study the impact of aero-thermal/optical window effects and airflow. This knowledge is essential for improving and confirming high-quality computer models, ensuring our simulations accurately predict what happens during hypersonic flights.

These AOK developments rely on relationships with several governmental agencies and GTFs to help develop and test aero-optic tools. AOK and associated research can be customized to support customers’ missions to defeat a myriad of emerging threats.

Polaris brings extensive expertise to the field, with a proven track record in planning, developing, and executing hypervelocity measurements, aero-optical modeling, and simulation.

The aero-optical instruments needed for testing at GTFs are large (4’x8’), unique to each facility, and need highly trained engineers to operate. Testing at more than one GTF is not uncommon, and some facilities lack the space for these traditional instruments. In response to these issues, Polaris is developing a solution called the Aero-Optics Kit (AOK).

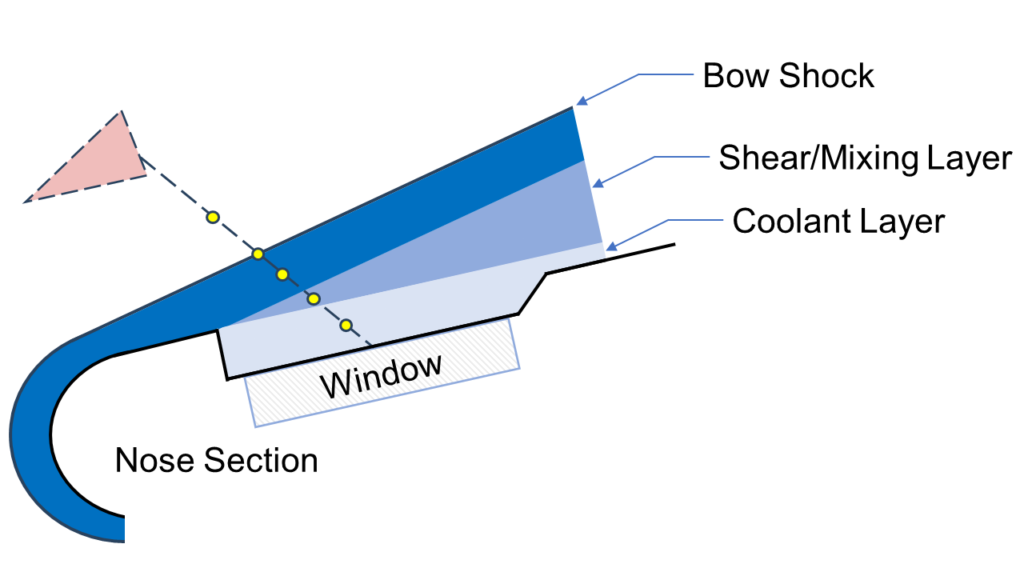

The AOK instrument suite optically interrogates hypersonic air flow interactions with airframes and quantifies the impact on seeker image performance. From within the test vehicle, the suite of sensors measures the total impact on an optical seeker as well as the separate component level contributions to seeker error from the window heating, bowing and flow layer interactions. The AOK provides the necessary data from ground tests to validate models and simulations, refine designs, and educate critical design choices.

The AOK provides real-time on-board measurements of aero-optical effects on seeker performance. It measures imaging performance, window effects due to aerothermal heating and pressure loading, and aerodynamic flow structures including turbulence with multiple, synchronized sensors.

The AOK mounts inside a test article having either a cooled or an uncooled window. The current AOK modules are designed to work with the Advanced Interceptor Technology (AIT) forebody test fixture for use in hypersonic test facilities. The instrument suite minimizes the need for specialized test setups and tunnel modifications.

Measurement accuracy is enhanced by using the same set of instrumentation within the same test fixture across several wind tunnels. The AOK encourages the widespread use of aero-optic test capabilities across different GTFs.

The AOK incorporates test fixtures completely within the interceptor test object. The source optics project a target from outside the test article, providing a more seeker-representative single-pass measurement. These factors eliminate the need for additional test structures and mounts in the flow, resulting in more accurate and reliable data.

The AOK minimizes the space and infrastructure requirements, making it more adaptable to different Ground Test Facilities (GTFs) without extensive modifications.

Each AOK Module pairs multiple sensors that validate one another in a single test run. This reduces the number of runs necessary to complete the characterization, saving both time and money, while sensor agreement ensures accuracy in the collected data.

Consistency in testing capabilities ensures that evaluations are comparable across different facilities, contributing to standardized and reliable results. Polaris has relationships with the nation’s foremost test facilities and experience instrumenting these facilities with AOK hardware.

Hypersonic aero-optics involves studying the impact of induced air flow around an airframe on the performance of an optical seeker during high-speed flight.

The AOK reduces space and infrastructure requirements, making testing more adaptable across different GTFs.

Polaris is here to help you solve challenging problems with cutting-edge technology. We will design, develop, and manufacture the solution you need to complete your mission.